Introduction to dissolved air flotation:

Dissolved air flotation belongs to the third generation of dissolved air flotation technology, which has four major disruptive technological innovations compared to the second-generation jet aeration dissolved air flotation, including: balanced dissolved air technology, adjustable non clogging rotary mixed air release technology, cyclone flocculation technology, and reverse concentration scraping slag technology.

Working principle:

1: Under pressurized conditions, air is dissolved in water to form an air supersaturated water state.

2: The supersaturated water in the air is reduced to atmospheric pressure, causing the air to precipitate. By releasing small and dispersed microbubbles dissolved in water, they adhere to the organic matter, oil, and suspended solids in the wastewater that have been condensed by adding chemical agents to form floating particles, thereby separating the organic matter, oil, and suspended solids from the wastewater.

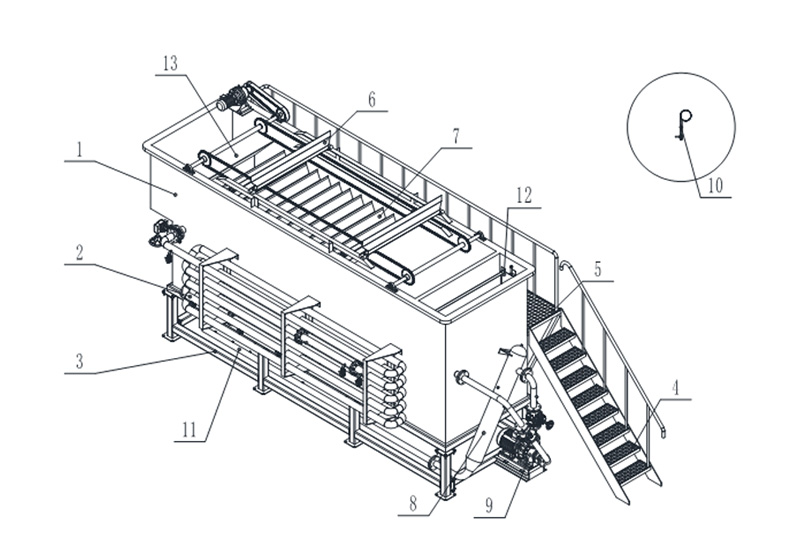

Structural diagram:

1. Air flotation body 2, cyclone flocculation coil 3, steel frame 4, ladder 5, platform 6, scraping slag removal system 7, steady flow plate 8, balanced air flotation dissolved gas tank 9, dissolved air pump 10, adjustable non clogging rotary mixed gas release device 11, dissolved air water pipeline 12, adjustable water tank 13, slag discharge plate

Product technical advantages:

1. Dissolved air flotation is a patented product of our company, with completely independent intellectual property rights.

2. The balanced air flotation dissolved gas tank is corrosion-resistant and gas resistant. It atomizes water twice and disperses it into the gas phase, with low pressure loss, large liquid gas contact area, small volume of dissolved gas tank, high dissolved gas rate, and good dissolved gas effect.

3. The adjustable and unobstructed rotary mixing release device is corrosion-resistant and gas resistant, with a smooth and open flow channel that can be adjusted without blockage. It can release pressure first, then release gas, and finally mix in steps, with high gas release efficiency, uniform bubble size, and good gas release effect.

4. The cyclone flocculation coil is corrosion-resistant and rust free, with no dead corners in the dosing reaction. It has good flocculation effect, saves chemicals, electricity consumption, occupies less land, has a beautiful appearance, and is clean and hygienic on site.

5. The reverse concentration scraping slag removal device has the advantages of minimal disturbance to the floating slag, a large number of scrapers, high scraping slag removal efficiency, and the ability to concentrate floating slag. The scraped floating slag has a low moisture content.

6. Compressed air is quantitatively transported to the air chamber of the balanced air flotation dissolved gas tank through a gas flow meter. The liquid level in the dissolved gas tank is constant, and the operation is stable and reliable.

7. The outlet weir plate is long, the load on the weir is small, the head loss is small, and there is no need to adjust during operation. The liquid level in the air flotation tank is constant.

8. The air flotation tank is equipped with a stabilizing plate to improve flotation efficiency, reduce the disturbance of the scraper plate on the floating slag, and achieve good air flotation effect.

9. The air flotation debugging is completed, and the di can be started directly after the second startup without the need for further adjustment. It has a high degree of automation, stable and reliable operation, and does not require personnel on duty.

Product application:

Application areas: Pre treatment of industrial wastewater such as slaughter, oil and fat, food, textile, printing and dyeing, papermaking, petroleum, chemical, pharmaceutical, leather, etc.

Significant advantages: SS removal rate of over 90%, with phosphorus removal function, fast removal of pollutants, no blockage, no odor, and good air flotation treatment effect.

Product Introduction: The universal balanced dissolved air flotation is a series of balanced dissolved air flotation products developed for general industrial wastewater such as slaughter, oil, food, textile, printing and dyeing, papermaking, petroleum, chemical, pharmaceutical, and leather industries. The universal balanced dissolved air flotation has many advantages, such as high SS removal rate, phosphorus removal function, high dissolved air rate, high gas release efficiency, no blockage, fast pollutant removal, no odor, good air flotation treatment effect, chemical saving, low water content of floating slag, stable and reliable operation, etc.

CN

CN

NEWS

NEWS

CONTACT US

CONTACT US