Project Introduction:

① In response to the problem of easy leakage in septic tanks, our company has developed an integrated equipment for sewage treatment and set up an automatic pumping function to avoid the problem of overflow of traditional septic tanks.

② Integrated equipment, integrated installation, only need to connect external pipelines, no need for professional personnel to operate, reducing installation costs.

③ The automatic decomposition of manure eliminates the need for manure trucks to transport it outside, reducing transportation costs and solving the problem of secondary pollution of manure.

④ Fully utilize the clean water from the decomposition of feces to flush the toilet, without the need for external tap water, reducing installation difficulties.

⑤ Circulating water for flushing toilets reduces water waste and is particularly suitable for arid and water scarce areas.

⑥ Through the microbial decomposition process, the emission of odors has been eliminated.

Project Execution:

Shandong Meiyang Environmental Protection Technology Co., Ltd. is a large-scale sewage treatment equipment manufacturing enterprise in China. Based on the advanced experience at home and abroad, it adopts advanced domestic sewage treatment technology and has developed a comprehensive treatment equipment for rural domestic sewage. Feces and sewage are treated by a four grid comprehensive sewage treatment system and used as toilet flushing water or irrigation water. It is like equipping each household with a set of small sewage treatment equipment, which does not require defecation, and the treated water meets the standards for toilet reuse and irrigation.

This device is divided into four systems:

One is the manure treatment system; The second is the toilet flushing system; The third is the overflow discharge system; The fourth is the automatic control system.

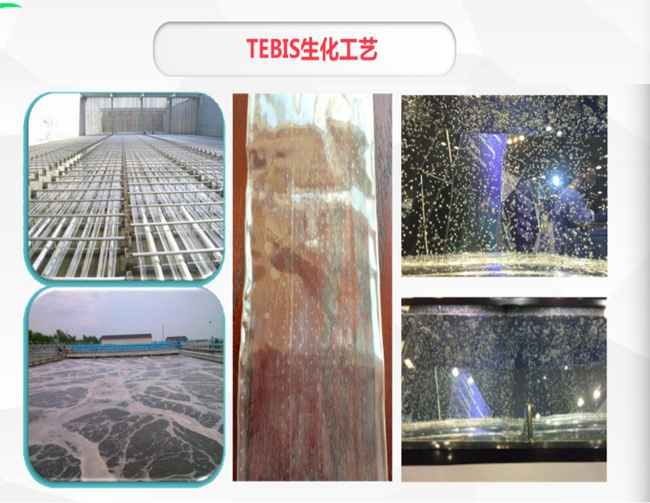

1、 The manure treatment system consists of four compartments, each connected by pipes. A pond is a first level anaerobic zone for defecation, where feces are incubated and fermented to kill parasites and bacteria through anaerobic treatment; The two tanks are a secondary anaerobic zone filled with fillers. Due to the high content of organic nitrogen in sewage, it will appear in the form of ammonia nitrogen during biodegradation. Therefore, the indicators of ammonia nitrogen discharged into the water will increase. Ammonia nitrogen is also a pollution control indicator. The anaerobic tank can use the nitrate brought in by the reflux mixture and the organic carbon source in the influent for denitrification, reducing NO2- and NO3- in the influent to N2 to achieve denitrification, while removing organic matter and degrading ammonia nitrogen values. The third tank is the aerobic zone, where the effluent from the anaerobic tank flows automatically into the aerobic biochemical tank. The aerobic biochemical tank is a biological treatment device that mainly uses biofilm method and also has activated sludge. Elastic packing is installed inside the aerobic biochemical tank to provide oxygen source for microbial growth. The organic matter in sewage is adsorbed and degraded by microorganisms, purifying the water quality. The fourth pond is a clear water area that can be directly reused or irrigated. The bottom of the pool is equipped with a reflux pump, which can reflux the bottom sludge to the anaerobic zone. If the sewage flow is too large and the sewage treatment is incomplete, the reflux pump will reflux the untreated sewage back to the anaerobic zone for reprocessing until it meets the standard.

2、 Toilet flushing system

The squat toilet does not require a dedicated water tank or external tap water. When flushing, only one control button needs to be pressed, and the clean water treated by the sewage treatment system can be pumped to the squat toilet through a small submersible pump. The flushing time can be freely set, and the remaining water will automatically flow back to the clean water area of the sewage treatment system. The system uses treated clean water for flushing, which fully saves water resources, and there is no water stored in the flushing water pipe, avoiding the problem of freezing and inability to use in northern areas in winter.

3、 Overflow discharge system

After the sewage tank is full, a dedicated float ball can be used to control the submersible pump to automatically extract treated water for irrigation or flow into the pipeline network, avoiding the indiscriminate flow of sewage on the street.

4、 Automatic control system

The equipment is equipped with an automatic control system, which includes automatic flushing, automatic drainage, automatic reflux, and automatic oxygen supply, ensuring the normal operation of the equipment while saving electricity.

Equipment installation picture:

CN

CN

NEWS

NEWS

CONTACT US

CONTACT US